Everyone knows that homes require a lot of maintenance. Things get old, they break down, kids do stuff (don’t think I need to explain that one), and life just happens. Home maintenance problems are a part of everyday life, a part we’d all rather live without, but part of it just the same, and they can be a real headache to deal with, and often cost a lot of money to fix. So it’s awesome that in this age of easily accessible information, we can always find helpful little articles on the internet about things like ‘how to fix a hole’ etc, turning us all into DIY geniuses! Or just mildly handy average Joe’s.

As a single parent to 5, there are a lot of challenges (yes, let’s call them that) which I am forced to deal with alone. Some of these challenges need to be sorted by someone qualified (or maybe semi-qualified if I’m on a tight budget), but more often than not, they are small problems that I can easily fix myself, or at least attempt to.

I look at these problems as welcome challenges, why? Because:

- They force me to learn a new skill

- Doing it myself saves me money

- The sense of accomplishment that comes from doing it myself, can’t be beat

- Doing it myself saves me money (I put this one twice because it’s the most important)

Recently one of my rather tall, lanky teenage sons, fell and put his elbow through one of the plasterboard walls in our house, leaving a hole about 6cm x 5cm (2.3 in x 2.8 in) in size. Lucky I love him or he would have been evicted that very day (joking…or am I?)

At first I was rather perturbed, wondering how I would sort this out without spending a fortune hiring a handyman (or some good-looking but not so professional “handyman want-to-be” from Airtasker) to fix it for me, and where on earth I would find the time to do it. But, after thinking on it for a while, I realised this was a great opportunity to be creative and resourceful, or show how un-handy I truly was. But, for this articles sake, let’s go with the former.

I realised I already had a few items lying around the house that could be useful, and I’d only need to spend a little bit of money (emphasis on the ‘little’) on the rest, which meant sticking to a budget would be easy. I wasn’t 100% sure my idea would work, which is often how I approach most of my projects, but once I had completed the job, I realised it was relatively cheap, easy and quick to do. I also discovered that little problems like this needn’t be scary and anxiety ridden, as more often than not, I have the ability and resourcefulness to take care of it, and since your reading this article, I’m betting you’re the kind of person that enjoys a challenge like this too.

So here is my low-budget step-by-step guide on how to fix a hole in plasterboard, which anyone can do. Seriously, anyone can do it, and in hindsight I should have gotten my wall-smashing son to do it, but then I wouldn’t have had a project to write a DIY article about would I?

Please note: This is just one of the ways you can fix a hole in plasterboard, there are certainly other ways to do it, which may or may not be easier and/or cheaper but this is how I did it and I hope by sharing this method with you, it will help someone else save some time and money.

This page contains affiliate links that may earn me a commission (without any extra cost to you) if you click on a link and make a purchase. Affiliate links are how I keep this blog running, thank you.

Supplies:

This is a short list of the supplies I used, and I emphasise ‘short’ because you really don’t need a lot to do this job. The links next to them are suggestions of where you might buy these items online (in Australia and the UK) if you don’t have them already. Otherwise, all of these items should be available from your local hardware store.

- Pair of scissors AU UK USA

- Quick-drying glue AU UK USA

- Cardboard (I just cut mine from a box)

- String or twine AU UK USA

- Sandpaper sponge AU UK USA

- All-purpose filler AU UK USA

- Plastic applicator AU UK USA

- Small paint roller with tray AU UK USA

- Sample pot of paint

Instructions (How to fix a hole):

Step 1:

Being the busy (or should I say muddle-headed) mum that I am, I forgot to take a photo of the hole before I started the repair but if you’ve seen one hole, you’ve seen them all, right? I don’t need to show you what a hole in your plasterboard wall looks like, as I’m sure you are staring at that problem right now.

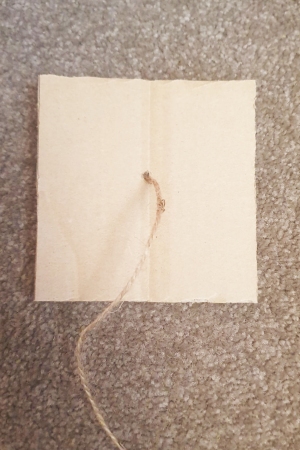

So, since I was using all-purpose filler, I needed something to cover the back of the hole so that the filler would have something to stick to and not just fall into the gap between the plasterboards, so I decided to use cardboard, cut from an old box. The next issue was how to get the cardboard onto the back of the hole, with no gaps. What I did was cut a square piece of cardboard slightly bigger on all sides than the hole. Then I poked a hole (yes, sometimes you need to make a hole to fix a hole) in the middle of the cardboard using the scissors, threaded through a piece of twine about 10 cm long and tied a knot at the back so the twine wouldn’t pull through. Yes I know, genius right? But it doesn’t end there.

Step 2

Next I put the glue (any quick-drying glue should work, I used wood glue I found in my workshop) around the edges of the cardboard on the side with the longest part of the string (so the pic you see above would be the ‘top’ of the cardboard) then folded the cardboard in the middle (trying not to touch the sides together) and inserted it into the hole and pulled on the string, adjusting the cardboard to make sure it covered the hole.

Make sure your glue is actually “quick-drying” unless you want to sit there all day, pulling on the string and waiting for it to dry. I mean you could do that if you want to, but make sure you have Netflix or some other streaming app installed on your phone before you start and that your phone is within reach. If you are smart enough (did I say that out loud) to use quick drying glue, it should be dry enough after a few minutes to let go of the string and snip it off just above the level of the cardboard.

Step 3

I left the glue to dry overnight, just to make sure it would stay in place when I filled it (or maybe just because I had other plans that afternoon, my memory is a little fuzzy), but with quick drying glue it should be good to go within about an hour or so (follow the instructions on the packaging). All-purpose or multi-purpose filler is a great option for this job, it’s quick drying and ready mixed and suitable for filling any small to medium cracks and holes in plasterboard and timber. I used Monarch Mini – Fill, Sand, Go from my local Bunnings store for $9.98. It came with it’s own sanding tool and applicator, so it took care of 3 of my supply needs in one little package.

Using the applicator (make sure you buy one if your filler didn’t come with one), I applied a liberal amount of the filler to the hole. Since it was on the larger side of a medium-sized hole, I found that it was difficult to get it smooth and flush with the wall, so I had to fill it, let it dry, then fill it again. Now you won’t be able to get it perfectly smooth like the metaphorical babies backside, but that’s what the sanding tool is for. If you don’t get a filler that includes a sanding tool, you can just use a sanding sponge or a block of wood with some 240 (or higher) grit sandpaper wrapped around it. I gave it a quick sand to smooth it out and felt pretty good about how it polished up.

This is what it looked like before sanding. I didn’t forget a pic (this time) of the sanded finish but I forgot everything I ever learnt about photography and didn’t keep the camera still, and the pic was just too blurry to use.

Step 4

This is the final step and I think the most fun. You’ll need to take a decent-sized chip of paint from your wall to the hardware store (say roughly the size of your kids elbow) so they can colour-match the paint. Ask for a sample pot size, as you don’t need much paint, and it’s still enough to keep in case one of your kids decides to put a knee or foot or other extremity through the wall again.

I used my cute little roller and baby roller tray, to paint over my filler and make the patch up job completely disappear. Hermione Granger eat your heart out!

Once the paint dried, you couldn’t tell at all, that there had been a teenage elbow sized hole there for about 3 months (I may be a bit of a procrastinator).

The Budget

So there it is, a quick and easy and let’s not forget affordable way to fix a hole in plasterboard on a budget. All up this project cost me around $21 (paint, roller, multi-purpose filler) as opposed to $100 – $150 to pay someone else to gain that sense of ‘pride in my accomplishment’, that was rightfully mine. Hopefully this has helped you to solve one problem in your life that could have been a headache (or aneurysm waiting to happen) and kept you from wasting money that could be better spent elsewhere (for instance on elbow pads for your clumsy teen).

Bosch PEX 220 A Orbital Disc Sander (Buy it Now)

Thanks

I hope you enjoyed this article and found it useful. If you’d like to read more DIY articles, head to our DIY MUM page or sign up to the DIY MUM newsletter by filling in the form below.

If you’d like to receive our Mum Life Stories newsletter and keep up to date with all our latest news, stories and promos (including giveaways & writing competitions) then why not sign up to our MLS email list. You’ll also receive a FREE Ebook, exclusive to email subscribers. Click HERE or fill out the form below.

More DIY Articles…

Get your FREE Ebook

The pace and intensity of our lives, both at work and at home, leave many of us feeling like a person riding a frantically galloping horse. Our day-to-day incessant busyness — too much to do and not enough time.

With this ebook you will learn to approach your days in another way, reducing stress and getting results through prioritizing, leveraging and focus!

Rustic Storage/Serving Tray From Reclaimed Wood (Buy it Now)

Rustic Storage/Serving Tray From Reclaimed Wood (Buy it Now)

Rustic 2-in-1 Storage/Serving Tray (Buy it Now)

Rustic 2-in-1 Storage/Serving Tray (Buy it Now)

So of course your going to want to remove the nails from your wood before you start working with it and the easiest way to do this is to hammer them out from underneath then use the back of the hammer to lever them out the rest of the way.

So of course your going to want to remove the nails from your wood before you start working with it and the easiest way to do this is to hammer them out from underneath then use the back of the hammer to lever them out the rest of the way. We used a circular saw to do this, but of course any electrical saw could do the job. It’s always a good idea to use safety glasses when cutting and sanding to prevent damage to your eyes should any wood chips fly up.

We used a circular saw to do this, but of course any electrical saw could do the job. It’s always a good idea to use safety glasses when cutting and sanding to prevent damage to your eyes should any wood chips fly up.